Get Better Measurement Results from Your Metrology Machine

Metrology is the science of measurements. But if you run a shop that depends on metrology machines for your work, you already know this.

There is no such thing as an all-purpose metrology machine. Every piece of metrology equipment is better suited to a specific task than another. And every shop has its own unique setup of equipment that works best for its processes and components.

From comparative gauges to coordinate measuring machines, touch trigger probes to vision systems, portable arms to laser scanners, there is a metrology machine for just about any application. Finding, or retrofitting, the optimal machine, however, takes a bit of know-how. And that’s something an independent metrology dealer can help you with.

The optimal coordinate measuring machine is all about matching function to application. A good place to start is comparing the actual measuring device. On a coordinate measuring machine this can be a touch probe system, a laser scanner, or a white light scanner.

RELATED ARTICLE: SHOULD YOUR BUSINESS BUY OR LEASE NEEDED EQUIPMENT?

Touch Probe Coordinate Measuring Machines

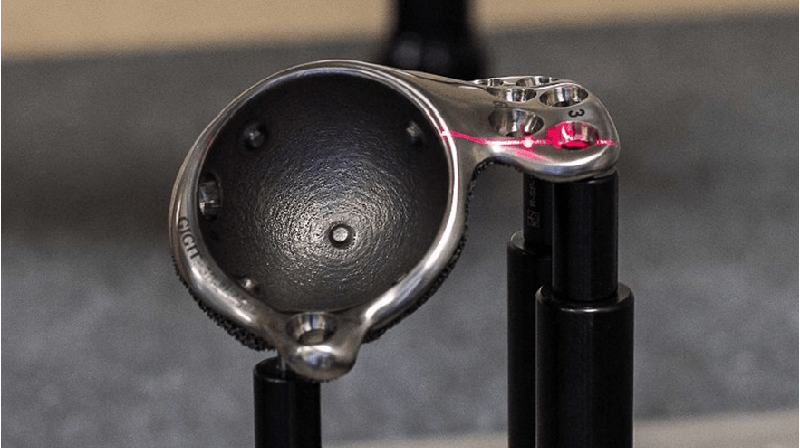

Touch trigger probes are the most common type of probing system you will find in coordinate measuring machines today. Their biggest advantage is precision. Each time a touch trigger probe makes contact with a point on a work piece, it sends an electronic signal that records that data point. Mounted on moving axes, you can rotate it manually or automatically. Automatic probing paths save a lot on labor hours.

Touch trigger probes can use a variety of styli tips, though the most common is synthetic ruby. You should use zirconia or silicon nitride as alternatives when the ruby faces abrasive or adhesive wear. For example, materials like cast iron can scratch ruby with tiny particles. And aluminum’s chemical affinity for ruby leaves an aluminum coating on the surface. You can stop by Cmmxyz.com for advice from expert metrologists on the type of styli tip your shop needs.

Laser Scanners on Coordinate Measuring Machines

In lieu of touch probes, you can also affix scanning systems to coordinate measuring machines. You can attach laser scanners to either a coordinate measuring machine or a portable arm. They are the most flexible non-contact measuring method, as they can measure all sides of a component regardless of where they are mounted. You can find laser scanning systems at metrology dealers like Canadian Measurement Metrology (CMM), who can also help you integrate them with your coordinate measuring machine. When you use these scanners in conjunction with software that interprets data points directly into 3D, your inspection and analysis process will proceed faster.

White Light Scanning Systems on Metrology Machines

Finally, there are white light scanners, the fastest method of collecting data on your components. According to CMM, they are best used when you’re inspecting small components or inspecting large quantities of the same component. This is because they can operate automatically with programming. Scanning and digitizing systems include the AICON PrimeScan, Leica T-Scan, WLS qFlash, and a number of other systems.

Conclusion

If you’re still wondering which system will work best in your shop, talk to a metrology dealer about getting better measurement results from your metrology machine. They can demystify metrology and help you to achieve optimum data collection results.

The post Get Better Measurement Results from Your Metrology Machine appeared first on Business Opportunities.

source http://www.business-opportunities.biz/2017/11/05/better-measurement-metrology/

No comments:

Post a Comment